Business

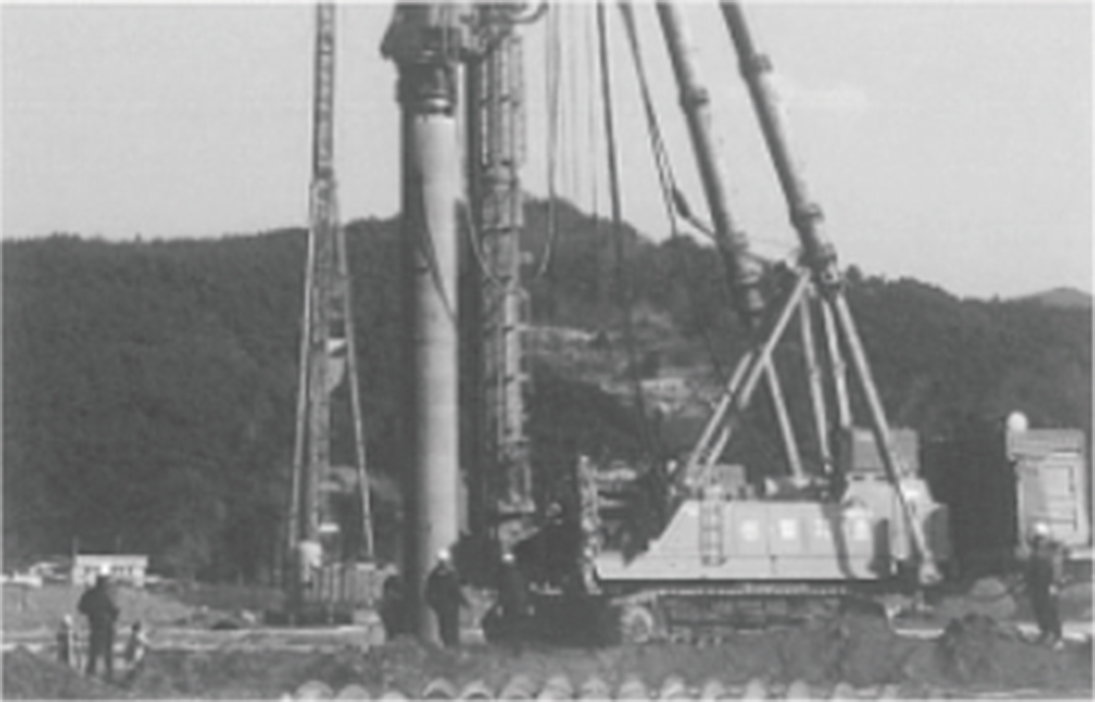

Due to the development of construction and engineering technology, and the efficient use of land, the increase in super high-rise buildings, the stabilization of load-bearing walls, and the reduction of construction costs have led to the introduction of large diameter piles to respond to market changes.

They can enhance seismic design using Rahmen structures.

They have strengths in the design of high-rise complex buildings.

They offer economic benefits by reducing material costs compared to the RCD method.

Plants

Ports

Land bridges

High-rise buildings

Marine bridges

Super-tall buildings

APT

| Type | Large-Diameter PHC Piles | RC Piles |

|---|---|---|

| Division |

|

|

| Advantages |

- Good quality of the pile body - Saves construction costs - Shortens construction period - Can be widely used for all pile construction |

Completed as a single, long pile without joints

|

| Disadvantages |

Joints are required as the depth increases

|

- Difficult to manage construction, making quality control challenging - Increases construction and material costs - Extends construction period - Difficult to ensure bearing capacity due to issues like rebar framework floating |

| Method |

SIP, SDA,(DRA), PIB

|

Earth drill, All casing, RCD

|

← Scroll please →